Duplex, Super Duplex or Super Austenitic Stainless Steel Fasteners

Stainless steel 304 and 316 are now a low cost solution but for corrosion application moreoften are not the best one; we can nowadays chose between a large range of corrosion resistant fasteners as duplex, super duplex, super austenitic alloy or the best performers nickel alloys and titanium. But what is the best one? Duplex, super duplex or super austenitic stainless steel fasteners? Is not easy to find the right technical solution and chose the best way to have a durable fixing systems without exceed with the costs. We can help you in this challege by using the following three tips.

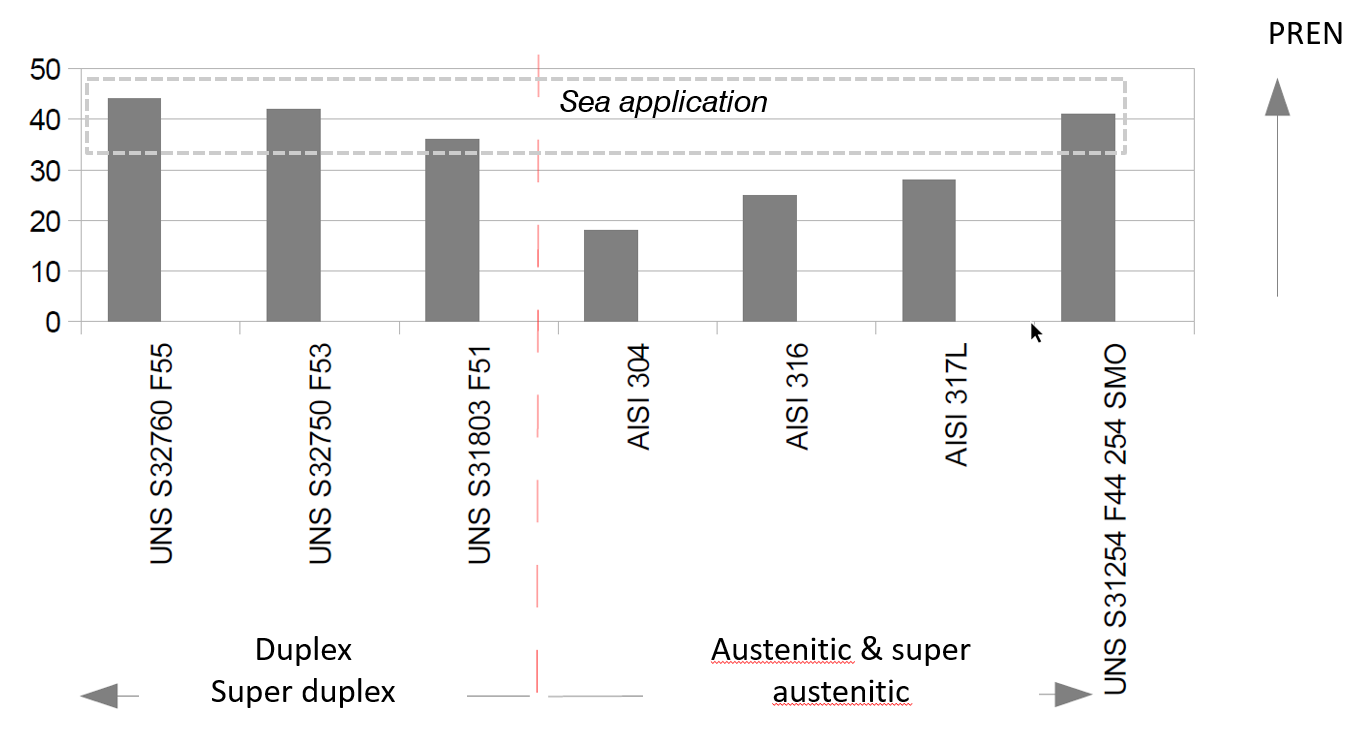

1 – Pitting resistance equivalent number (PREN):

PREN is a predictive measurement of a stainless steel’s resistance to localized pitting corrosion based on its chemical composition. In general: the higher PREN-value, the more resistant is the stainless steel to localized pitting corrosion by chloride. This value is frequently specified when stainless steels will be exposed to seawater or other high chloride solutions. In some instances stainless steels with PREN-values > 32 may provide useful resistance to pitting corrosion in seawater, but is dependent on optimal conditions. However, crevice corrosion is also a significant possibility and a PREN > 40 is typically specified for seawater service.

Calculate your PREN :

PREN = 1 x %Cr + 3.3 x %Mo + 16 x %N

PREN = 1 x %Cr + 3.3 ( %Mo + 0.5 x %W ) + 16 x %N (with tungsten alloy)

Higher PREN number means higher corrosion risistance; the best performance stainless steel fasteners are:

2 – Mechanical property

Indeed choise the suitable material for the specific application, also comes from the evaluation of the mechanical characteristics. The materials commonly used for the production of fasteners in corrosive applications are those belonging to the duplex, superduplex and superaustenitic families. Table below show the indicative mechanical characteristics of the materials belonging to the above mentioned families.

In case of high resistance performing fastener needs in addiction to standard super duplex corrosion resistant fasteners, MF INOX could provide super duplex UNS S32760 – 2507 – F55 bolts, screws and studbolts with ultimate tensile strenght up to 1050 MPa.

3 – Performance Vs Cost

Duplex, super duplex, super austenitic alloy are nickel chrome base materials, so the high nickel percentage alloy, means high material cost. Herewith bellow an example:

| Type | Ni % | Cost |

| A182 F51/UNS S31803/2205 | 5.60 | low |

| A182 F53/UNS S32750/ | 6.10 | medium – low |

| A182 F55/UNS S32760/2507 | 17.5 – 18.5 | medium – high |

| A182 F44/UNS S31254/254SMO | 23.0 – 28.0 | high |