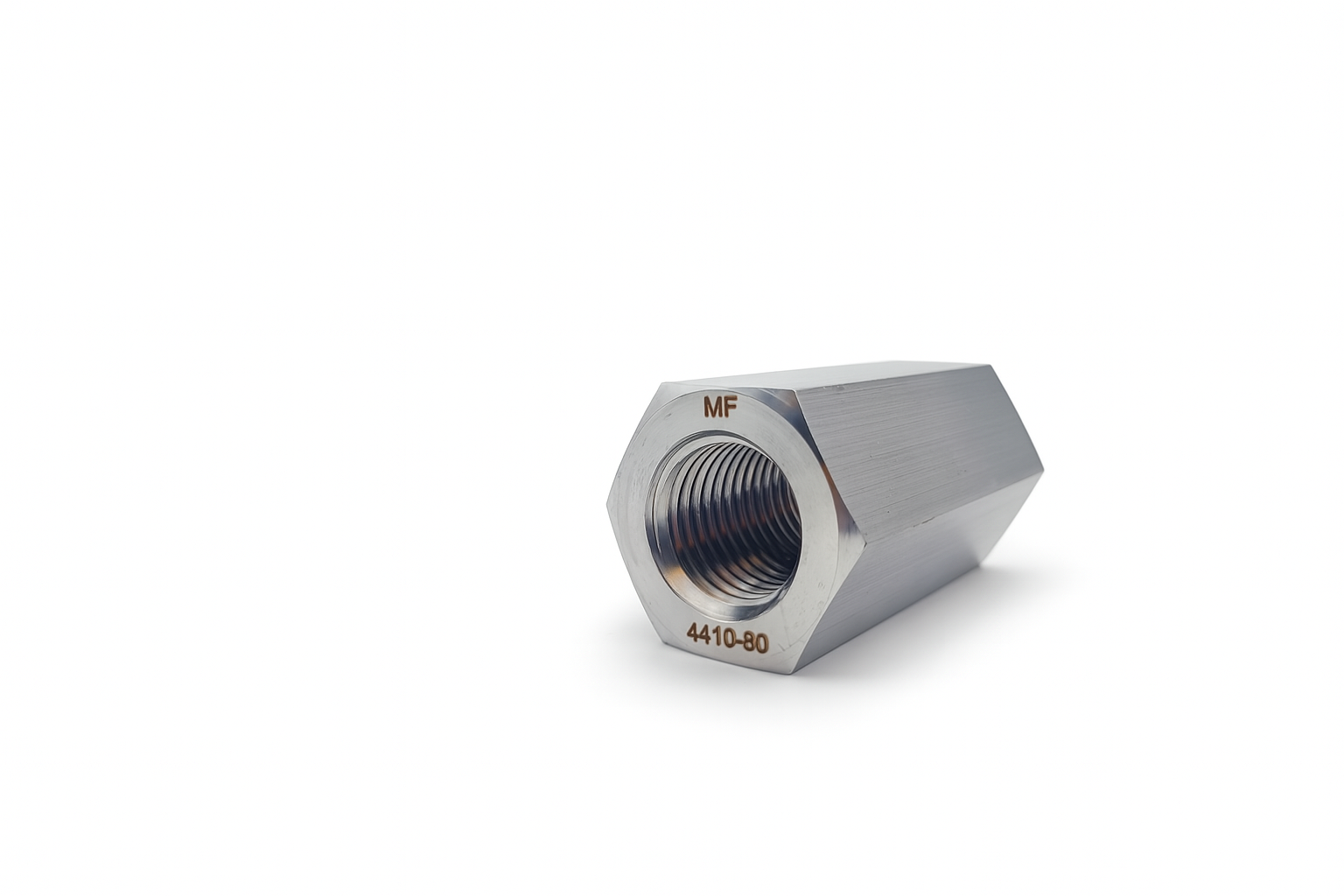

Use of DIN 6334 in infrastructure projects

DIN 6334 is widely used in civil and industrial engineering projects. It is used extensively to make mechanical connections in tunnels, bridges and plant support systems. Its configuration makes it possible to create secure extensions of threaded rods at hard-to-reach connection points, while maintaining mechanical tightness even under thermal expansion or vibration.

It is therefore ideal for maintenance work, temporary installations or structural consolidations, where fast and reliable fixing are essential requirements.

Types of materials for critical environments

To meet corrosion resistance requirements in environments exposed to moisture, chemicals or salt spray, DIN 6334 can be made in a wide range of materials:

- AISI 316L (1.4404) stainless steel: for general outdoor applications

- Super Duplex 1.4410: high resistance in highly corrosive and temperature change environments

- Austenitic alloy steel 1.4539 (Alloy 904L): excellent resistance to acids and seawater

- Alloy steel 1.4529: advanced anti-corrosion performance, suitable for tunnels in cold environments, where there is a strong presence of salt needed to reduce the risk of ice formation on the road surface, and marine structures

With these solutions, the DIN 6334 nut proves to be a reliable choice for installations in tunnels, underpasses, power plants, offshore structures and complex industrial facilities.

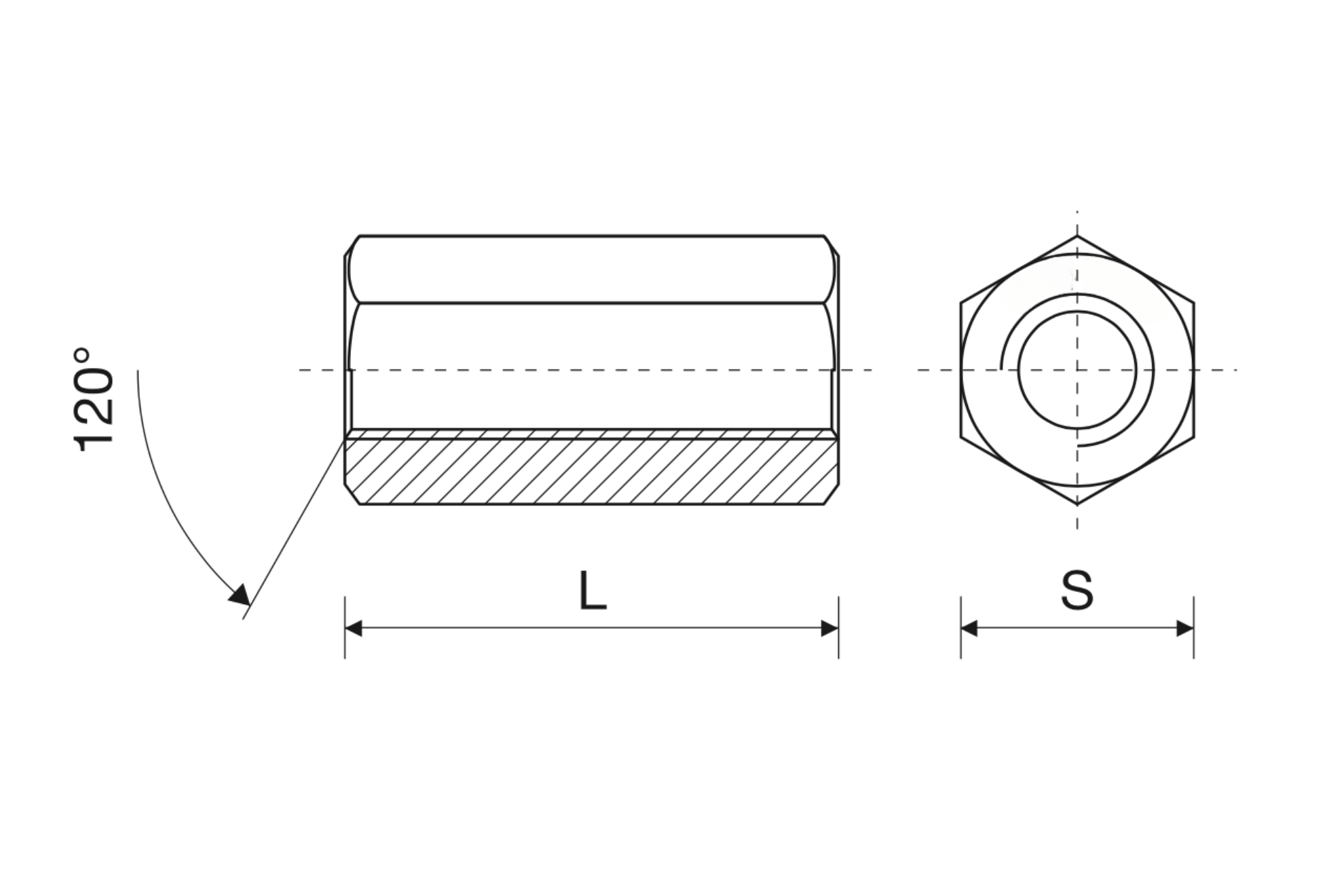

Technical specifications and available variants

The metric coarse pitch internal thread of the DIN 6334 nut allows for simple, secure and torsion-resistant coupling. The main configurations available are:

- Inox A2 (1.4301): suitable for indoor and low-aggressive environments

- Inox A4 (1.4401): for outdoor environments or in contact with water

- Special steels: for extreme conditions on request

The lengths are standardized according to the standard, but MF INOX can make variations on drawings to suit any type of project.

Why choose MF INOX for DIN 6334 joint nuts

At MF INOX, we offer a complete range of DIN 6334 nuts with quick delivery and dedicated technical support. The availability of certified raw material in different alloys allows us to provide urgent solutions as well. We work according to major international standards, with attention to quality, technical documentation and traceability.

Thanks to our production flexibility and experience in the infrastructure and plant engineering sector, we guarantee tailor-made solutions for all splicing and extension needs in critical environments.

| for M thread | M 6 | M 8 | M 10 | M 12 | M 16 | M 20 | M 24 | M 30 | M 36 |

|---|---|---|---|---|---|---|---|---|---|

| L (length) | 18 | 24 | 30 | 36 | 48 | 60 | 72 | 90 | 108 |

| S (key) | 10 | 13 | 17 | 19 | 24 | 30 | 36 | 46 | 55 |