Expertise

MF Inox has been producing fasteners to international standards, to customer specification and to drawing in nickel alloys, stainless steel and titanium since 1992.

Flexibility in order management, our smart structure, combined with the skills of our team, allow us to be time-to-market oriented.

We offer technical support services to our clients, working closely together to develop fastening solutions that not only optimally meet functional requirements, but are also the most cost-effective thanks to the wide range of materials we can offer. We are known in the market as a specialist in the hot forging of stainless steel and superalloy screws and nuts suitable for high and low temperature and corrosion-resistant applications. We produce parts suitable for hostile environments in the oil & gas, energy, infrastructure, marine and submarine, naval and railway sectors.

We are known in the market as a specialist in the hot production of stainless steel and superalloy screws and nuts suitable for high and low temperature and corrosion-resistant applications. We make parts suitable for hostile environments in the oil & gas, energy, infrastructure, marine and submarine, naval and railway sectors.

Stamping

hot stamping

Machining

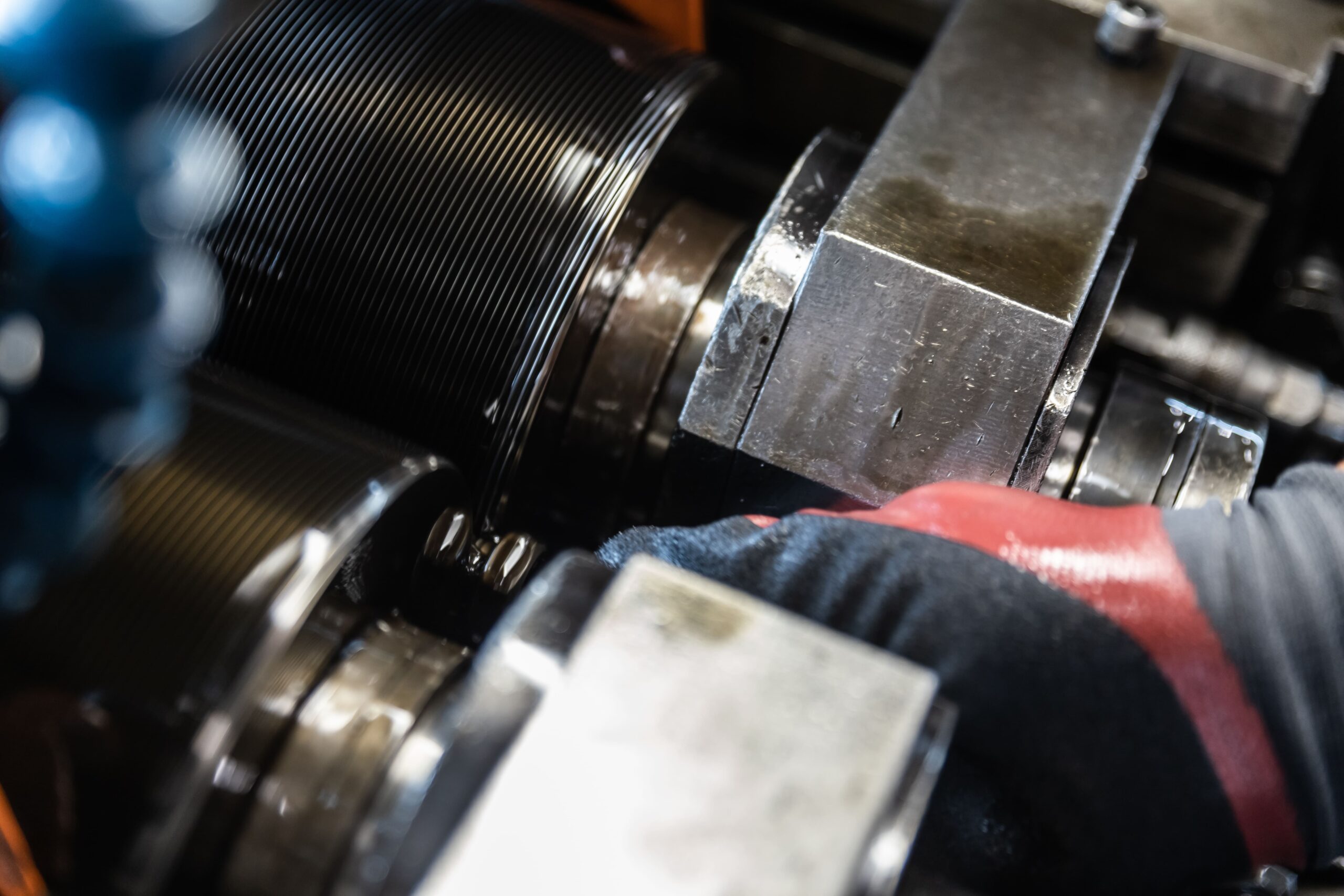

Thread

rolling

Heat Treatments

Range of materials

The most commonly used materials for our screw, nut and tie rod production are duplex A182 F51 UNS S 31803, super duplex F53 UNS S32750,

Corrosive environments

Producing ISO 3506-compliant fastening systems for corrosive environments has always been in our DNA. Whether they are systems made of materials

High temperature

In our product range, we include components made for applications in the presence of high temperature, over 1000°C, ensuring compliance

Low temperature

DIN 267-13, EN 10269, ASTM A320 define the properties of materials suitable for low-temperature applications. M.F. Inox also offers

High strength

Increasing the mechanical strength characteristics of fasteners means reducing their size and consequently their weight and cost.

Production range

Our production allows us to make both standard parts according to European UNI- DIN- ISO- EN - EF Anglo-Saxon BS and American